TOUGHENER FOR REACTIVE RESIN SYSTEMS

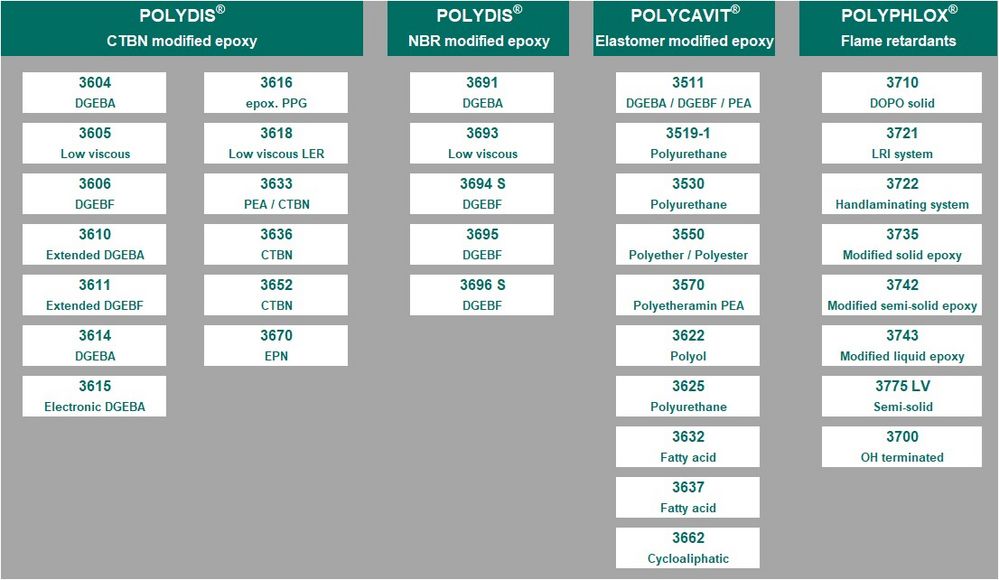

STRUKTOL® POLYDIS® CTBN Modified Epoxy Resins,

STRUKTOL® POLYCAVIT® ELASTOMER Modified Epoxy Resins

Reactive, duromeric resin systems, such as epoxy and polyurethane resins, have excellent thermal and mechanical properties. Consequently, these matrix systems are widely used for the formulation of high-strength adhesives and for the production of composite parts (fiber composites). However, duromers often exhibit high brittleness to impact stresses.

With STRUKTOL® POLYDIS® and POLYCAVIT® tougheners, both the brittleness can be reduced and other important properties such as

- impact strength,

- tensile shear strength,

- flexibility,

- thermal stability

can be significantly improved. Tougheners can be added at up to 20% when formulating a resin system.

STRUKTOL® POLYDIS® CTBN Modified Epoxy Resins are classical tougheners made of epoxy resins reacted with reactive rubbers. STRUKTOL® POLYCAVIT® ELASTOMER Modified Epoxy Resins are based on rubber-free elastomers or hybrid elastomer types.

CTBN MODIFIED EPOXY RESINS

CTBN modified epoxy resins are prepolymers that are obtained by reaction of nitrile rubber with epoxy resins. These versatile products offer significant improvement in technical properties such as impact strength, tensile shear strength, flexibility and adhesion to oily steel.

Typical applications are adhesive formulations, coating systems, casting resins, prepregs and epoxy resin systems in the fiber composite industry.

NBR MODIFIED EPOXY RESINS

NBR modified epoxy resins are prepolymers that are formed by the reaction of nitrile butadiene rubbers with epoxy resins. These products are particularly suitable for increasing tack in adhesive and prepreg resin formulations and for adjusting the resin flow of prepreg systems (resin flow).

ELASTOMER MODIFIED EPOXY RESINS

The elastomer modified epoxy resins are rubber-free prepolymers that are created by the reaction of polymers with epoxy resins. The polymers used for this purpose primarily belong to the following groups: dimer fatty acids, polyols, polyurethanes, polyetheramines or thermoplastics.

These products, like CTBN-modified epoxy resins, improve technical characteristics such as impact strength, lap shear strength and adhesive strength. Depending on the modification, the handling of the rubber-free epoxy resins is easier, with an improvement in performance similar to the CTBN-modified epoxy resins.

Typical applications are adhesive formulations, coating systems, casting resins, prepregs and epoxy resin systems in the fiber composite industry.