STRUKTOL® POLYDIS®, POLYVERTEC® and POLYPHLOX® Additives for Prepregs in Composite Applications

Composites based on prepregs are used in a wide range of applications:

- Aerospace industry: aircraft fuselages and wings, empennages.

- Transportation (rail, marine): railcar construction, ship superstructures

- Wind energy: rotor blades

- Sports and leisure industry: golf clubs, bicycles, fishing rods, etc.

Prepregs are textile fiber semi-finished products that are pre-impregnated with reactive resins such as epoxy resins. For the production of very high-quality fiber composite components, prepregs are cured in the form of laminates under pressure and temperature.

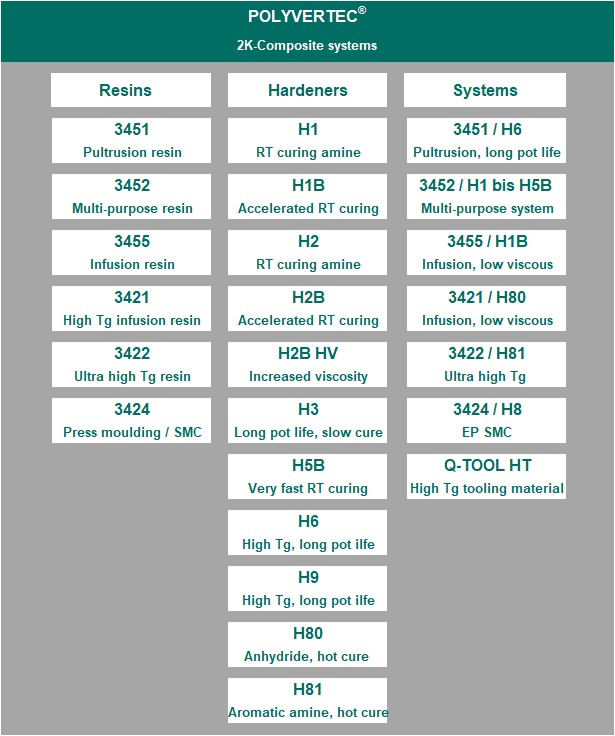

With STRUKTOL® POLYDIS® and POLYVERTEC® modifiers, e.g. the tack and mechanical properties such as toughness of the prepreg material can be specifically adjusted and increased. In this way, high-performance composite parts (CFRP/GFRP) can be produced, which are often characterized by very low weight and extreme strength and stiffness.

STRUKTOL® POLYPHLOX® Flame Retardant modifiers based on halogen-free phosphorus compounds improve the fire behavior of the material and composite parts made from it.

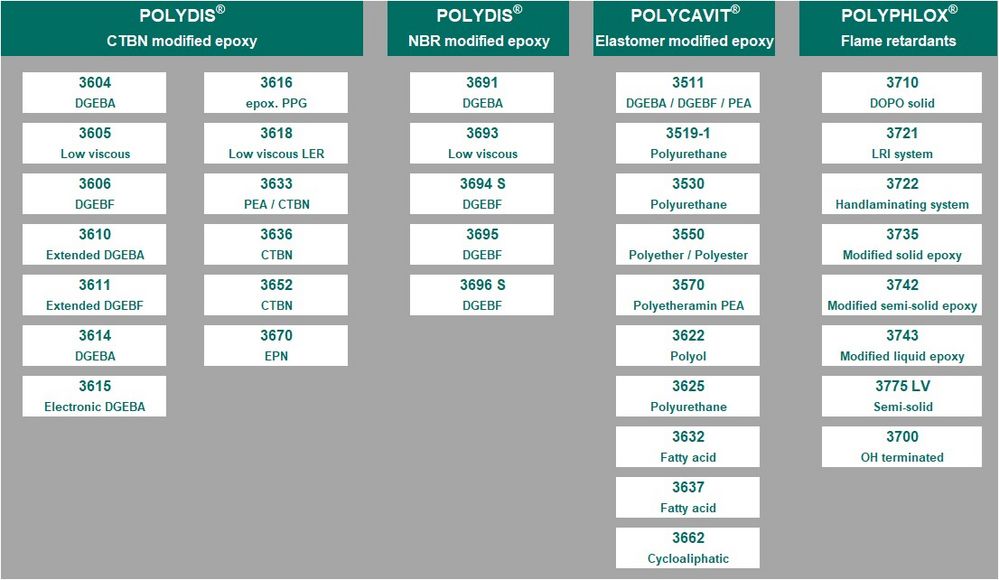

CTBN MODIFIED EPOXY RESINS

CTBN modified epoxy resins are prepolymers that are obtained by reaction of nitrile rubber with epoxy resins. These versatile products offer significant improvement in technical properties such as impact strength, tensile shear strength, flexibility and adhesion to oily steel.

Typical applications are adhesive formulations, coating systems, casting resins, prepregs and epoxy resin systems in the fiber composite industry.

NBR MODIFIED EPOXY RESINS

NBR modified epoxy resins are prepolymers that are formed by the reaction of nitrile butadiene rubbers with epoxy resins. These products are particularly suitable for increasing tack in adhesive and prepreg resin formulations and for adjusting the resin flow of prepreg systems (resin flow).

ELASTOMER MODIFIED EPOXY RESINS

The elastomer modified epoxy resins are rubber-free prepolymers that are created by the reaction of polymers with epoxy resins. The polymers used for this purpose primarily belong to the following groups: dimer fatty acids, polyols, polyurethanes, polyetheramines or thermoplastics.

These products, like CTBN-modified epoxy resins, improve technical characteristics such as impact strength, lap shear strength and adhesive strength. Depending on the modification, the handling of the rubber-free epoxy resins is easier, with an improvement in performance similar to the CTBN-modified epoxy resins.

Typical applications are adhesive formulations, coating systems, casting resins, prepregs and epoxy resin systems in the fiber composite industry.

FLAME RETARDANTS

Reactive flame retardants based on phosphorous-organic compounds such as DOPO are a very effective and toxicologically safe alternative to halogen-containing flame retardants.

STRUKTOL® POLYPHLOX® products are chemically pre-treated so that they later react with the matrix in epoxy resin systems. This has little effect on the mechanical and chemical properties of the cured EP matrix, so that for many applications the respective optimum property profile and good fire protection (e.g. UL94 V0) can be achieved.

The products can often be combined well with synergists such as APP, melamine cyanurates or ATH, so that the fire protection effect can be further enhanced.