Reactive Resins and Systems

POLYVERTEC® COMPOSITE SYSTEMS

STRUKTOL® POLYVERTEC® COMPOSITE SYSTEMS for composite applications and potting compounds

Fiber reinforced components (composites) based on reactive resin systems are used in many application areas:

- Transportation (rail, shipping): railcar construction, ship superstructures

- Wind energy: rotor blades

- Sports and leisure industry: golf clubs, bicycles, fishing rods, etc.

- Gliders: fuselage, wings and tail unit

- Construction industry: stiffening elements, lamellas and re-bars ("construction steel mats")

- Potting compounds

The properties of POLYVERTEC® COMPOSITE SYSTEMS can be adapted within wide limits to meet the different requirements of processing procedures as well as the properties of the finished fiber composite component. For the production of high-quality infusion and RTM molds (tooling), POLYVERTEC® Q-TOOL HT can be easily processed as a quartz-based polymer concrete in a casting process.

POLYVERTEC® COMPOSITE SYSTEMS can be combined in many ways with other STRUKTOL® products, such as POLYPHLOX® Flame Retardant modifiers or the STRUKTOL® POLYDIS® and POLYCAVIT® Tougheners product range.

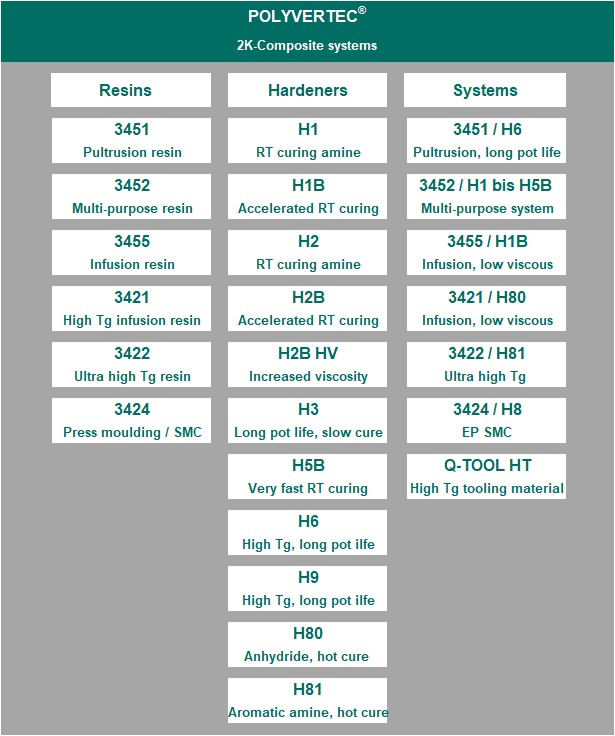

EPOXY RESIN SYSTEMS

The epoxy resin systems are already compatible resin/hardener combinations that meet specific requirements. They only have to be mixed by the user in the recommended mixing ratio. Depending on the selection, the final thermal and mechanical properties can be influenced.

Typical applications are adhesive formulations, coating systems, casting resins and epoxy resin systems in the fiber composite industry.

EPOXY RESINS

The epoxy resins are the A-component in a resin-hardener system. In addition to the standard epoxy resins based on bisphenol-F and bisphenol-A, special, multifunctional resins as well as cycloaliphatic EP resins are used. In combination with the appropriate hardener/accelerator, glass transition temperatures of up to 270°C and high mechanical properties can be achieved.

HARDENERS

The hardeners are the B-component of a resin system that cures the matrix. For this purpose, substance classes such as amines or anhydrides etc. can be used, either alone or in mixtures. In this way it is possible to react and adapt to the conditions from room temperature to hot curing.

TOOLING CASTING MATERIAL

Tooling casting compounds are 2-component epoxy resin systems which are mixed with a specially adapted mineral filler such as quartz. This allows (prototype) moulds to be created for the production of fibre composite components, which can be adapted to different requirements such as pressure and temperature stability, depending on the combination of resin system/mineral filler. The applications range from the replacement of PU block materials to moulds milled from aluminium. Correspondingly, molds can be produced that have a CTE of aluminum with a high Tg >200°C and very high compressive strength at high temperatures. These molds can also be used for RTM processes.