Tackifier & Flowcontrol FOR PREPREGS

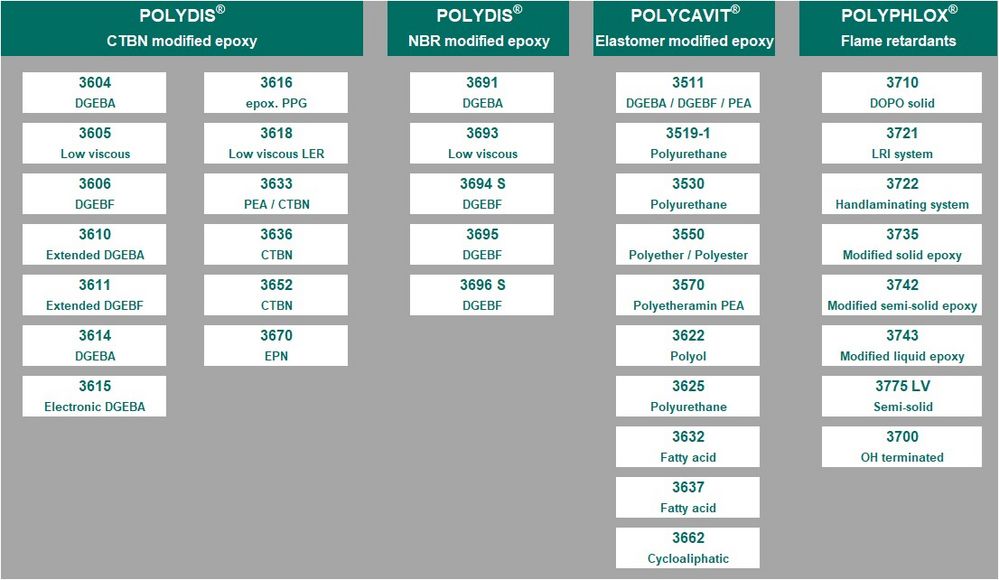

STRUKTOL® POLYDIS® NBR Modified Epoxy Resins

STRUKTOL® POLYCAVIT® ELASTOMER Modified Epoxy Resins

Prepregs are textile fiber semi-finished products that are pre-impregnated with reactive resins. For the production of fiber composite components, prepregs are processed into laminates and cured under pressure and temperature.

By using modifiers of the STRUKTOL® POLYDIS® NBR Modified Epoxy Resins series

- the tack and

- the resin flow (controlled flow)

of prepreg resins can be specifically adjusted to simplify the processing of the prepreg and to control the resin flow of the material during curing. Both of these features considerably support manufacturing companies in the production of high-quality composite parts and help to reduce production costs.

In addition, the toughness of the cured material can also be increased as important mechanical properties.

NBR MODIFIED EPOXY RESINS

NBR modified epoxy resins are prepolymers that are formed by the reaction of nitrile butadiene rubbers with epoxy resins. These products are particularly suitable for increasing tack in adhesive and prepreg resin formulations and for adjusting the resin flow of prepreg systems (resin flow).

ELASTOMER MODIFIED EPOXY RESINS

The elastomer modified epoxy resins are rubber-free prepolymers that are created by the reaction of polymers with epoxy resins. The polymers used for this purpose primarily belong to the following groups: dimer fatty acids, polyols, polyurethanes, polyetheramines or thermoplastics.

These products, like CTBN-modified epoxy resins, improve technical characteristics such as impact strength, lap shear strength and adhesive strength. Depending on the modification, the handling of the rubber-free epoxy resins is easier, with an improvement in performance similar to the CTBN-modified epoxy resins.

Typical applications are adhesive formulations, coating systems, casting resins, prepregs and epoxy resin systems in the fiber composite industry.